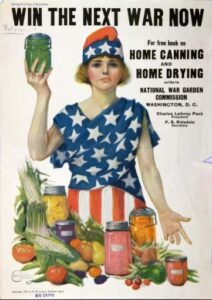

Home canning, or jarring as it’s often called in Europe, has a fascinating history rooted in war, science, and innovation. What began as a military necessity during the Napoleonic era evolved into one of the most trusted and rewarding methods of food preservation worldwide. Today, home canning stands at the intersection of tradition and technology—offering both a link to our ancestors and a path toward sustainable living.

(I sometimes use affiliate links in my content. This will not cost you anything but it helps me offset my costs to keep creating new canning recipes. Thank you for your support.)

By Diane Devereaux | The Canning Diva®

Last updated: October 6, 2025

Key Takeaways

- Home canning originated in France during the Napoleonic Wars—not America—and was refined through centuries of innovation.

- Nicolas Appert’s experiments with glass jars laid the foundation for food preservation as we know it.

- Louis Pasteur’s discoveries on microorganisms and heat gave birth to pasteurization and safe canning principles.

- Denis Papin’s 17th-century “Digester” inspired the modern pressure canner.

- Today, water bath and pressure canning methods use time, temperature, and acidity to ensure food safety and longevity.

The History of Home Canning: From Napoleon’s Challenge to Modern Preservation

Home canning’s story begins not in a farmhouse kitchen, but on the battlefield. In 1803, during the Napoleonic Wars, France was struggling to feed its soldiers. “An army marches on its stomach,” Napoleon famously said, recognizing that hunger—not enemy fire—was weakening his forces. By the time fresh foods reached the front, they had spoiled, leaving troops to scavenge or buy from locals.

In a bold move, Napoleon’s government offered a 12,000-franc reward through the Society for the Encouragement of Industry to anyone who could develop a method to preserve food for the army.

After 14 years of experimentation, Nicolas Appert—a French chef, confectioner, and distiller—claimed the prize in 1810. He discovered that cooking food in sealed glass jars prevented spoilage unless air was allowed in. Appert successfully preserved soups, fruits, vegetables, juices, dairy products, marmalades, jellies, and syrups.

With his prize money, he founded The House of Appert (1812–1833), the world’s first commercial cannery. Though he didn’t yet understand the microbiology behind it, Appert’s process became the foundation of thermal preservation—a technique still central to canning today.

Louis Pasteur and the Birth of Pasteurization

Half a century later, Louis Pasteur revealed what Appert could not explain: that microorganisms cause spoilage. His experiments showed how heat, time, and acidity could be controlled to destroy harmful microbes.

Pasteur’s work led to the invention of pasteurization—the process of heating foods and beverages to eliminate pathogens before cooling them. This discovery confirmed what home canners had practiced for generations: boiling water destroys germs, and heat is key to food safety. Pasteur’s work transformed Appert’s art into science and formalized thermal processing as a food safety standard.

The Early Days of Pressure Canning

While water bathing worked beautifully for high-acid foods, another approach was needed for low-acid ingredients like meats and vegetables. The idea of pressure-aided heat actually dates to 1679, when Denis Papin invented the Digester, an early pressure cooker. Papin’s sealed vessel drove temperatures above boiling, proving the power of pressurized heat—though without modern safety valves, his prototypes sometimes exploded.

Jump to the 20th century: in 1905, Northwestern Steel and Iron Works (later National Presto Industries) began producing large “canner retorts” for commercial use in Eau Claire, Wisconsin, then scaled to home-size models by 1915. In 1917, the U.S. government recognized pressure canning as the reliable way households could reach higher temperatures needed for low-acid foods. By 1925, the company was renamed the National Pressure Cooker Company.

Fun fact: During World War I, entire loaves of bread were baked and canned in tin to keep troops fed on the front lines—proof that the power of pressure and heat could preserve not only meats and vegetables, but even fresh-baked goods!

As canning science matured, researchers quantified how time and temperature work together to destroy heat-resistant spores. In 1946, the government adopted privately authored white papers and consolidated them into USDA Technical Bulletin No. 930. That bulletin did not proclaim “pressure or nothing.” Instead, it compiled thermal death data and explained how D-values (time at a given temperature), Z-values (temperature sensitivity), and F-values (total lethality) guide safe processes. The widely cited 240°F (116°C) appears there as a reference temperature used for calculations and tables, not as a one-size-fits-all rule. In practice, we use a pressure canner to process low-acid foods because it’s the practical household method to reach higher temperatures than boiling water, while water bath canning remains appropriate for high-acid foods where 212°F (100°C) plus acidity provides the needed lethality.

As I discuss in The 240°F Myth: Botulism, Heat Resistance, and the Misunderstood Pressure-Only Mandate, this number was never intended to be a universal requirement. It simply represented the temperature needed to reach microbial lethality under specific test conditions from the 1940s. Modern home canners now know that time, density, and pH play equal roles in achieving thermal kill—not just hitting a single temperature threshold.

This scientific pivot—from anecdotes to time–temperature math—sets up the two thermal processing methods we rely on today.

The Two Methods of Thermal Processing

Because of centuries of experimentation and scientific discovery, we now use two safe and effective canning methods: water bath canning and pressure canning. The choice between them depends on acidity (pH) and food density, both of which determine the time and temperature needed for proper preservation.

Water Bath Canning

High-acid foods (pH 1.0–4.6) such as fruits, jams, jellies, and pickled vegetables are safely processed using boiling water. At 212°F (100°C), harmful microorganisms are destroyed, ensuring shelf-stable jars.

Pressure Canning

Low-acid foods (pH above 4.6), such as meats, beans, and root vegetables, require higher temperatures—typically 240°F (116°C) or more—to eliminate Clostridium botulinum spores and other dangerous bacteria. Pressure canning achieves this by trapping steam, which raises the internal temperature well above boiling.

It is the overall pH and density of the recipe that dictate the required processing time and temperature—not simply the type of food being canned.

Home Canning in the 21st Century

Today’s canners benefit from centuries of refinement. Modern pressure canners feature precision gauges, venting systems, and multiple safety locks, allowing us to preserve a broader range of recipes with confidence and consistency.

From hearty Beef Burgundy and Chicken Pot Pie to creative chutneys, salsas, and shrubs, canning has evolved from mere preservation to culinary artistry. Chutney, shrubs and salsa have been expanded upon and are quite the highlight when water bathing. What I find exciting however are the many recipes still in circulation, passed down from generation to generation that still line our pantry shelves bringing a piece of history into our homes. Across the globe, families continue to celebrate this enduring craft—mixing science, history, and flavor in every jar.

Home canning has always been about more than just food—it’s about community. Hosting a Canning Party brings people together, turning work into joy and tradition into shared memory. As the saying goes, “Many hands make light work.” Whether you’re new to canning or have been filling jars for decades, you’re part of a living legacy that connects past to present—one lid at a time.

Quality by Vision wrote a fun timeline chronicling this amazing craft throughout the centuries. It is fun to lean when various items were introduced to society such as when we started canning food for our military and when we actually started to commercially can food in America – all the while thousands of us steadfastly canning and home preserving in our home kitchens.

Where ever you are in your canning and preserving journey, know you have centuries of tradition sealed in every jar. Be sure to check out my cookbook, The Canning Diva Presents Meals in a Jar, if you are interested in learning ways to preserve delicious meals in a jar and safely customize your canning recipe.

People Often Ask

A: Nicolas Appert, a French chef and confectioner, developed the first successful method of sealing cooked food in glass jars in 1810. His discovery laid the foundation for modern home canning and thermal preservation.

A: Pressure canning evolved from Denis Papin’s 1679 invention of the Digester, which used steam pressure to reach temperatures above boiling. In the early 1900s, companies like National Presto Industries refined the concept into safe, practical canners for home use.

A: No. The USDA adopted privately authored white papers in 1946 that established mathematical relationships between time and temperature for bacterial destruction. These studies were compiled into Technical Bulletin No. 930 and later standardized into processing guidelines for home canning.

A: The two approved thermal processing methods—water bath and pressure canning—reflect differences in food acidity. High-acid foods (pH 4.6 or lower) can be safely processed in boiling water, while low-acid foods (pH above 4.6) require the higher temperatures achieved through pressure canning.

About the Author:

Diane Devereaux, The Canning Diva®, is an internationally recognized food preservation expert, author, and educator with over 30 years of home canning experience. She’s the author of multiple top-selling canning books and teaches workshops across the U.S. Learn more at TheCanningDiva.com.